In developing innovative new precious metal alloys, watchmakers are working to make timepieces both tougher and more beautiful than ever

The word precious may refer to something valuable, but don’t forget it can also mean fussy, finicky and difficult. Both interpretations apply when talking about precious metals. Gold, for instance, possesses reassuring heft and, thanks to its inert nature, is hypoallergenic. But in its unadulterated form, it’s too soft and malleable to be used in jewellery or watchmaking: it can easily lose shape or be scratched or dinged.

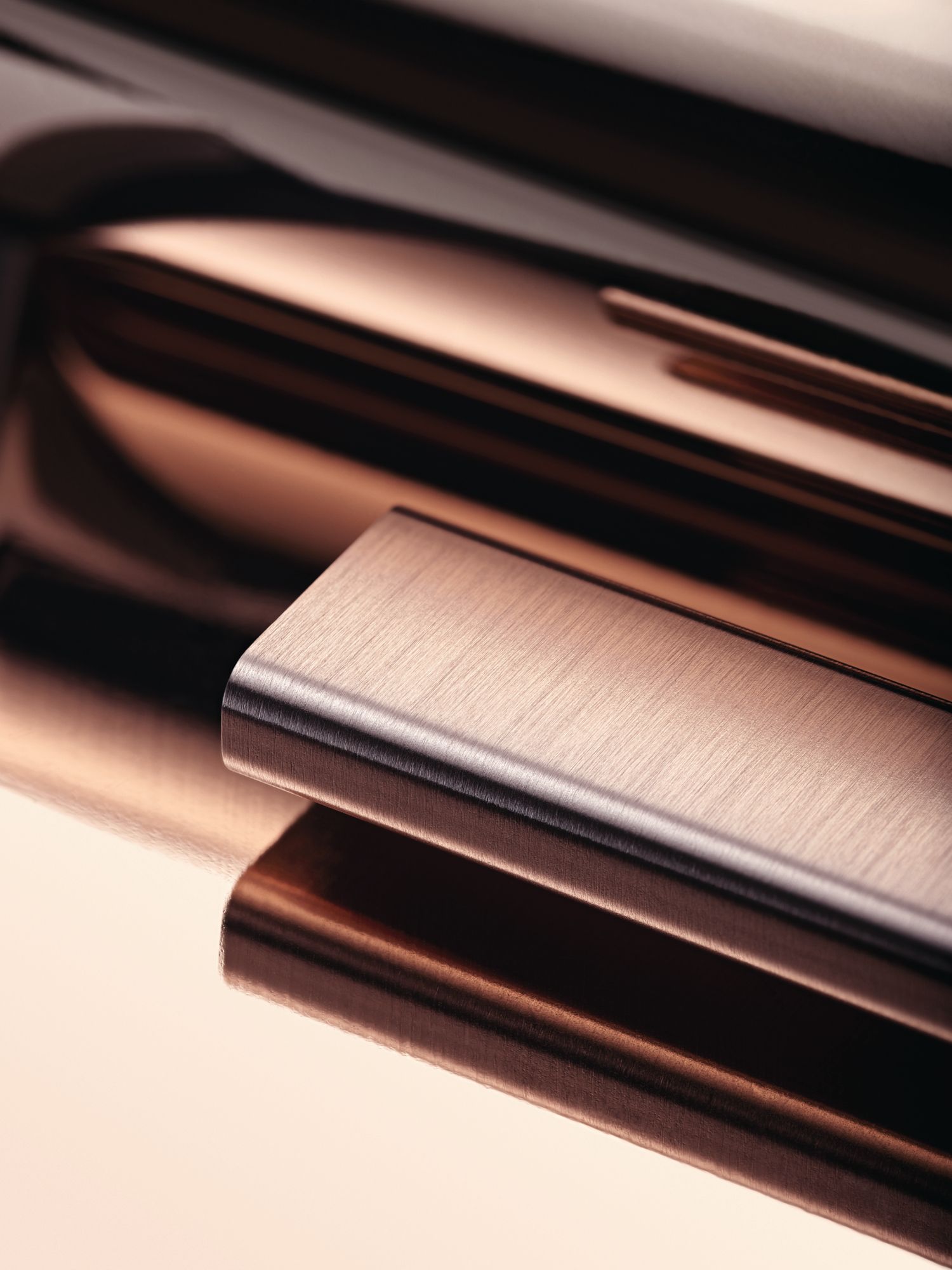

That’s why jewellers and watchmakers have long added a dash of more rigid materials to precious metals, creating alloys of vastly improved stability and strength. There’s been little innovation in the formulation of alloys over the past few hundred years. Most watchmakers contentedly use 18k gold, comprising about 75 per cent gold, 12.5 per cent copper and 12.5 per cent silver in the case of yellow gold; 75 per cent gold and 25 per cent copper for red gold; and 90 per cent gold with 10 per cent nickel for white gold. However, in recent times, a number of forward-thinking houses of horology have begun developing new, proprietary alloys that eliminate certain shortcomings of traditional blends.

Custom Made

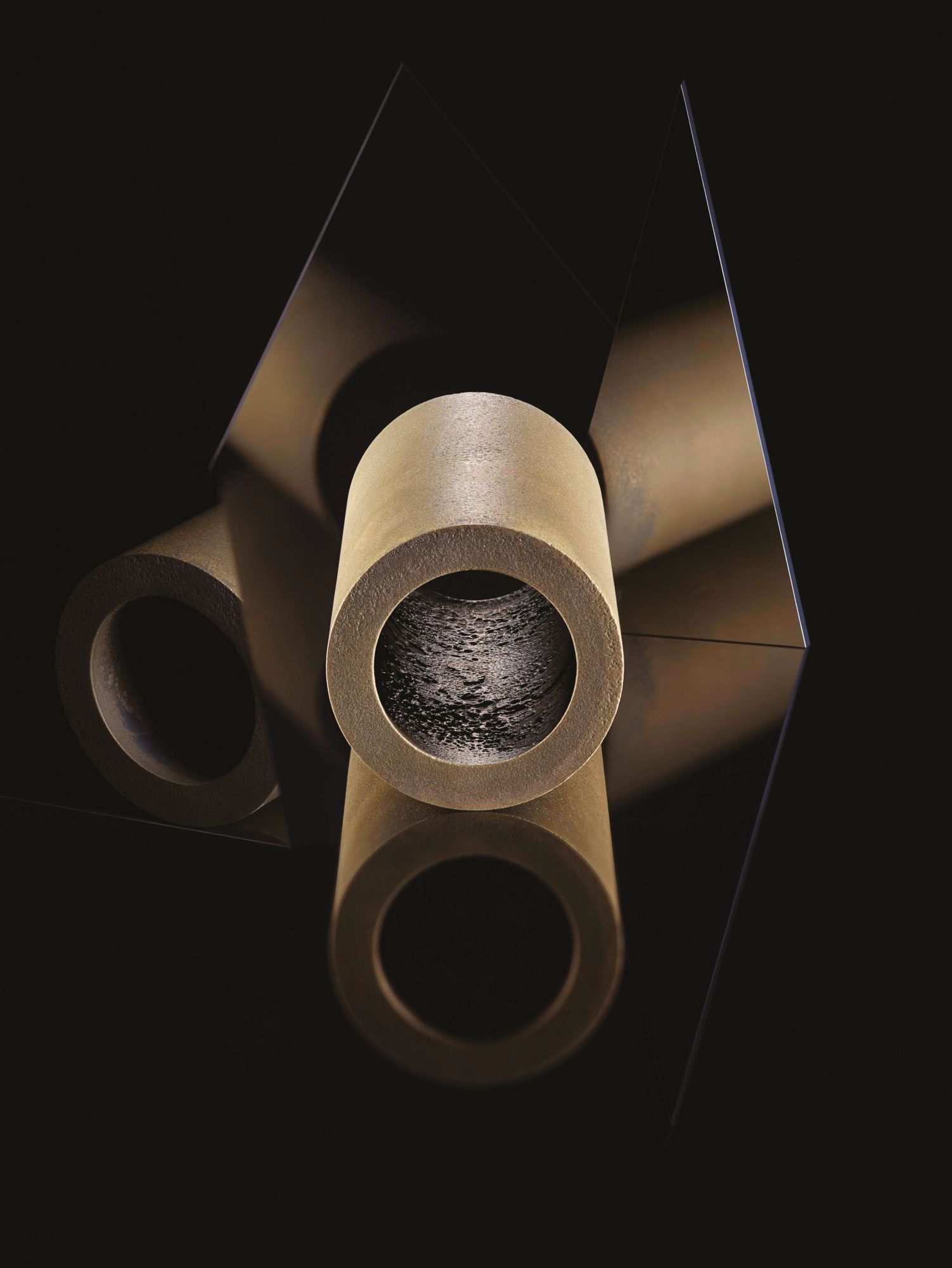

Watchmaker Hublot applies the corporate philosophy The Art of Fusion to the realm of materials. The company has created patented mash-ups including Hublonium, made of magnesium and aluminium; Texalium, a carbon/aluminium composite; King Gold, a vibrant 18k red gold alloy with boosted copper content and platinum to stabilise the colour and neutralise oxidation; and Magic Gold, which the company claims is “the world’s first and only” scratch-proof 18k gold/ceramic.

“We invest heavily in research and development—not least, in the innovative materials used in Hublot’s watches," says CEO Ricardo Guadalupe. “We want to bring a real spectacle to the watch you show on your wrist.” Likening the brand’s use of inventive materials to its creative approach to collaborations—ranging from artists and musicians to sportsmen and tattooists—Guadalupe says. “Owning a Hublot reflects an affinity with an eclectic group of aesthetics, influences and affiliations.”

See also: Pomme Chan Wears Hublot And Reflects On The Creative Process